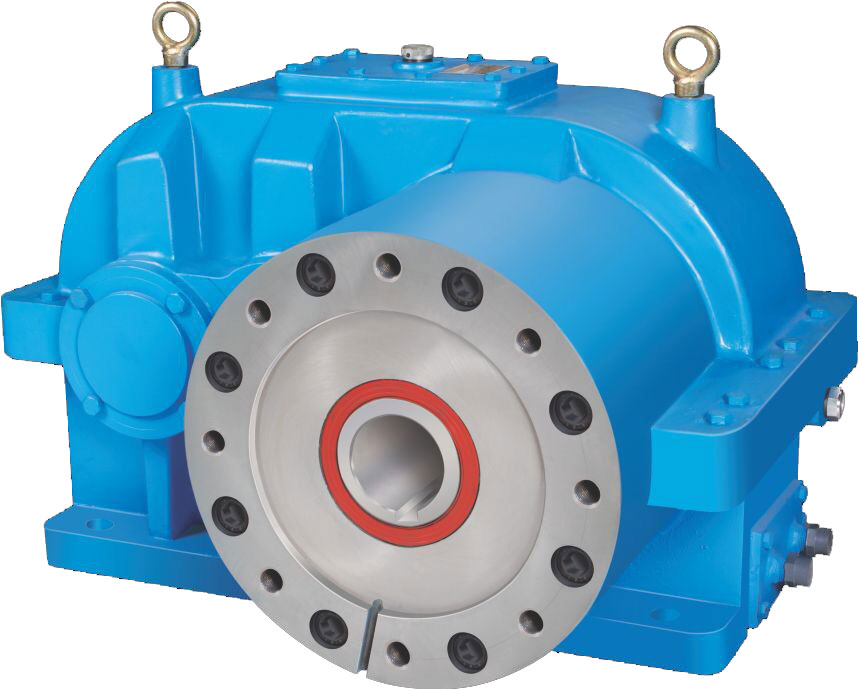

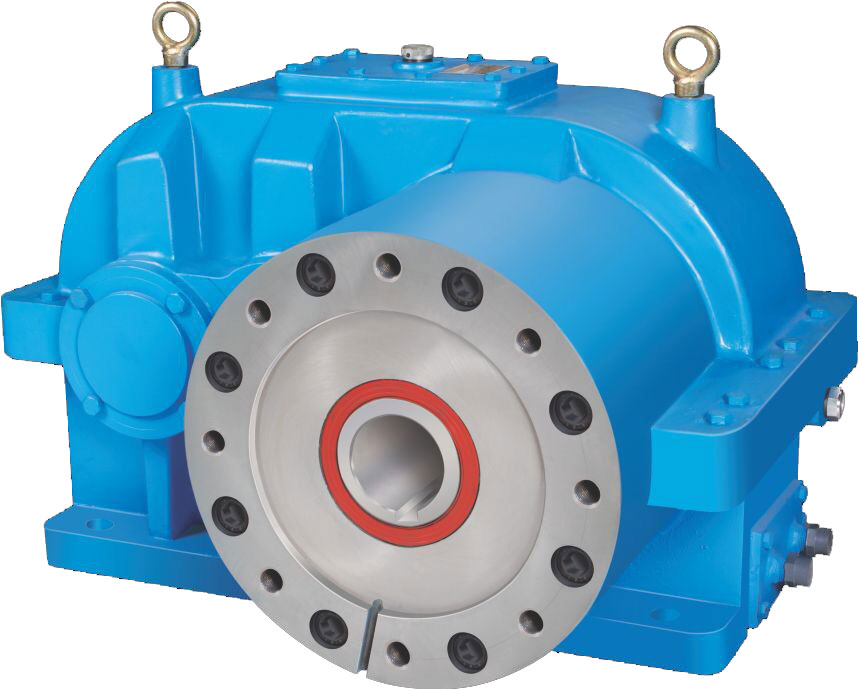

Extruder Gear Box

Extruder Gear Box

- Designed for the best transmission

- High efficiency and torque

- Sufficient safety factor

- Excellent heat dissipation

Reliable, durable and space saving

Our Extruder Gear Boxes are designed for high reliability, and durability with a compact design that enables space savings.

Reduced operational costs & power consumption

High efficiency of the extruder gear box enables our gear boxes to reduce operational costs and lower power consumption.

Excellent heat dissipation

Designed with precision and our extruder gear boxes have excellent heat dissipation properties and hence excellent performance

extruder gear boxes

Comet “Power Drive” extruder gear boxes are designed in double reduction version with thrust bearing housing integrally cast to horizontally split case. Gears and pinions are of helical type manufactured from high quality alloy case-hardening steel. Lubrication of gears and bearings is entirely self-contained by automatic splash which provides ample positive flow. Cooling happens with heat dissipation via convection or radiation.

- High quality close grained cast iron casting

- Horizontally split 2 pieces for accommodating bearings and gear trains

- Flank ground gears and pinions to precision to ensure high standard of accuracy

- Quiet running characteristics

- Tapper roller bearings that have ample capacity to support combined radial and thrust loads.

‘Power Drive’ Product Range

- Designed for the best transmission

- High efficiency and torque

- Sufficient safety factor

- Excellent concentricity and levelness to ensure accuracy

- Excellent heat dissipation